Current State of Post-Accident Operations at Fukushima Daiichi Nuclear Power Station July to December 2015 ~Nuke Info Tokyo No. 170

State of the Plant

Many of the measuring instruments installed in the Fukushima Daiichi Nuclear Power Station (FDNPS) measuring system continue to malfunction as a result of the accident and there is no guarantee of the accuracy of values being measured. However, from the water temperature in the containment vessels and the spent fuel pools, and from the state of releases of Xenon-135, which is released when uranium undergoes fission, and other measurements, it can be estimated that the state of the reactors is stable.

State of Post-Accident Operations

1. State of Operations concerning Spent Fuel Pools

Removal of all of the fuel assemblies stored in the Unit 4 spent fuel pool (SFP) was completed on Dec. 22, 2014.

Measures are being implemented at Unit 3 to reduce the radiation dose level in preparation for the work of removing the fuel. Work for removal of large pieces of debris from the SFP was completed on November 21, 2015. Thus far, it has been confirmed that there are six deformed fuel assemblies.

The work to dismantle the cover in place around the Unit 1 reactor building began on May 15, and removal of the roof panels was completed on October 5.

Approaches for dismantling the upper section of Unit 2 reactor building were considered and it was decided to completely dismantle the section above the top floor of the building. Dismantling of buildings in the surrounding area began in September in preparation for removal of the fuel.

2. The Problem of Contaminated Water

According to an estimate by Tokyo Electric Power Company (TEPCO), roughly 800-1,000 m3 of groundwater is flowing into FDNPS Unit 1 to 4 per day, about 300 m3 of which is flowing into the reactor buildings.

TEPCO is implementing seven different kinds of measures to suppress the flow of groundwater:

- Groundwater pumping wells have been installed on the mountain side of the site to pump up groundwater and release it into the ocean after measuring its contamination level. This “groundwater bypass” for reducing the inflow of groundwater began operation in April 2014. A total of 154,021 m3 of water have been released (up to December 21, 2015). In October 2015, TEPCO estimated that, combined with the water suppression measures taken at the high-temperature incinerator building, this operation reduced the groundwater inflow by 80 m3 per day.)

- Installation of a sea side water barrier to prevent contaminated water leaking out with groundwater. The construction work was completed in October 2015, but due to a rise in the level of groundwater, which now had no outlet, the water barrier warped and a fissure appeared between the ground and the barrier. Repairs were completed on December 5.

- Groundwater is being pumped up from the pumping wells, known as sub-drains, that have been dug around the buildings, and this being released into the ocean after processing at the water processing facility for water from the sub-drains and other locations. This measure began operation in September 2015. Around 360 m3/day of water are being pumped up and a total of 36,376 m3 had been released as of December 21, 2015.

- Groundwater is being pumped up from pumping wells known as groundwater drains, five of which were dug in the vicinity of the sea side water barrier, and is being released into the ocean after processing at the water processing facility for water from the sub-drains and other locations. This operation began in November 2015, when the groundwater level rose. Around 90 m3/day are pumped up for a total thus far of 14,380 m3. The groundwater level is being adjusted in combination with groundwater pumping (80 m3/day) using well points which began operation in August 2013.

- Construction of an inland water barrier (creation of a frozen earth water barrier by burying 1,568 refrigeration pipes and 359 temperature measuring tubes at set intervals around Units 1 to 4.) The preparation for freezing was completed on the three inland sides on September 15 and the work to install the refrigeration pipes of the remaining sea side was completed on November 9. Trial freezing, which began on April 30 at 18 locations using 58 freezing tubes, showed differences in freezing temperature, but TEPCO has assessed the freezing trials as having no problems.

- Implementation of removal of highly contaminated water flowing from the buildings into trenches on the sea side. Work on Unit 4 to stop water flows and to remove contaminated water, was conducted in two stages and completed on April 28 and December 21, for Unit 2 on July 10, and for Unit 3 on August 27.

- Operation of the Advanced Liquid Processing System (ALPS – three existing systems, three additional ALPS systems, and a high performance ALPS system) to separate contaminants, including nuclides, from contaminated water, although tritium still remains in the treated water, and to reduce the strontium content of concentrated salt water.

On August 11, the Fukushima Prefectural Federation of Fisheries Cooperative Associations approved the troubled plan to release treated water pumped up from the sub-drains and groundwater trenches into the ocean. Five conditions, including strict implementation of water quality management and a continuation of compensation, were agreed to as part of the approval.

TEPCO estimates that the operations 3. and 4. above that were begun on the basis of the approval have reduced the inflow of groundwater into the buildings by 200 m3/day. The plan to release treated groundwater that had up to now been allowed to flow into the ocean once the sea side water barrier had come into operation has had to be abandoned because the groundwater pumped up was found to be so highly contaminated that it could not be processed by the water processing facility for water from the sub-drains and other locations. As a result, the volume of water transferred to the building for treatment by ALPS is increasing (around 400 m3/day as of December 18). The total inflow to the reactor buildings increased to 600 tons per day.

3. Removal of Fuel Debris

Work needed to reduce the radiation dose inside Unit 1 in order to inspect the inside of the reactor containment vessel is under way. Preparations are being made for an internal inspection of the containment vessel by robot, following on from similar attempts in April 2015. Robots are now being developed for an internal inspection of the containment vessel of Unit 2. In October, an inspection device was dispatched to the inner cavity of the reactor containment vessel of Unit 3 and it was confirmed that the internal dose level there was lower than in other units (around 1 Sv/h). Further, an inspection of the reactor containment vessel equipment hatch was carried out using a small device in November.

4. Others

The number of workers at FDNPS was around 2,950 daily as of March 2013, but in March 2015 this had increased to 7,450, and even in November this figure was 6,450. On August 8, a fatal accident occurred while a vacuum car was carrying out cleaning work. This was the third fatal industrial accident to have taken place during the post-accident work at FDNPS, the previous cases having occurred in March 2014 and January 2015.

(Hajime Matsukubo, CNIC)

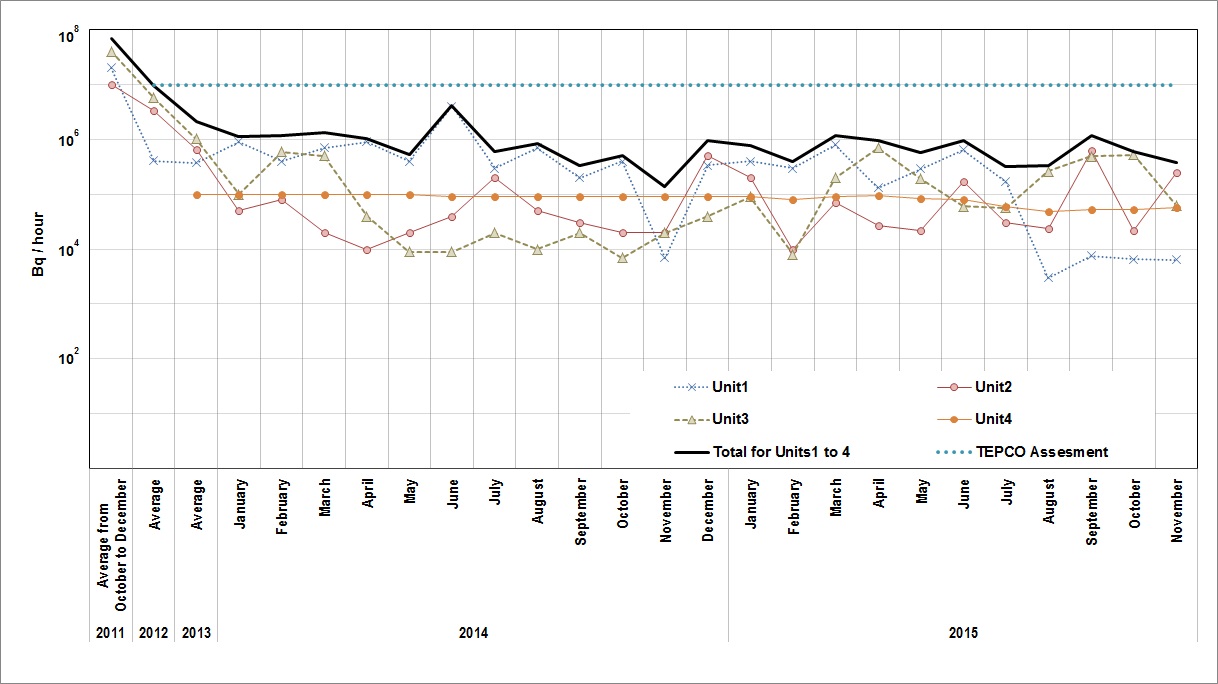

Figure 1: Releases of radioactivity from Units 1 to 4 of Fukushima Daiichi Nuclear Power Station (Bq/h)

*An assessment by TEPCO shows 10 million Bq/h up to May 2014 and less than 10 million Bq/h after May 2014